Poles and Particles

Magnetics Design

We design magnetic pole tips for 3DFM and MHTS systems as needed for magnetics experiments. Force experiments rely upon new particle designs for studies of cells, cilia and molecular motors.

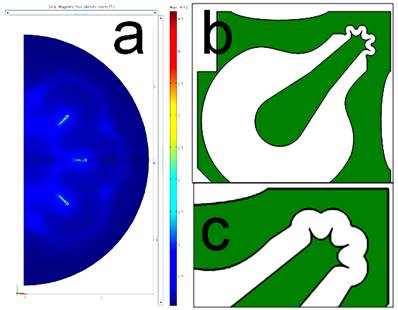

Pole tips:The utility of the 3DFM and MHTS magnetics systems depends on the pole tips that determine the field (and hence force) geometry at the within the experimental chamber, and the magnetic probe particles that attach to the specimen. For the shaping of the magnetic field, there is, in general, a trade-off between achieving high field gradients for high forces, and having that force remain constant over a significant area. Within the MHTS, we would like to maximize the beads in each well that experience useful forces, and so we choose to optimize a combination of force and useful area, a so-called “force-area product”.

Pole tips:The utility of the 3DFM and MHTS magnetics systems depends on the pole tips that determine the field (and hence force) geometry at the within the experimental chamber, and the magnetic probe particles that attach to the specimen. For the shaping of the magnetic field, there is, in general, a trade-off between achieving high field gradients for high forces, and having that force remain constant over a significant area. Within the MHTS, we would like to maximize the beads in each well that experience useful forces, and so we choose to optimize a combination of force and useful area, a so-called “force-area product”.

For the design of the pole tips, we simulate the magnetic fields generated for each of a range of designs. We have experience for such COMSOL-based simulations from our design of the 3DFM magnetics. For high force-area product designs, we have begun testing on a comb structure that increases the number of pole tips within the well. We have achieved significant forces within the comb area, exceeding 1 nN on a 4.5 micron diameter magnetic bead. These forces are similar to those achieved using our simple “pole-flat” design

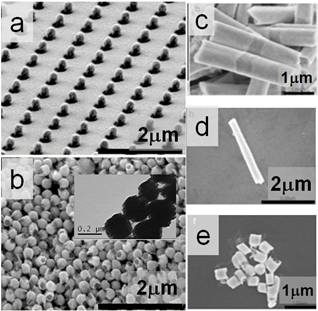

Particles:Force measurements within intracellular trafficking experiments require magnetic particles that mimic endogenous vesicles, and therefore need to be in the size range of 300nm or less in diameter (uniform magnetic particles of this type are not commercially available). A second requirement is chemical and special specificity of attachment. One example is the case of cilia studies, where we seek to attach one bead to only one cilium. We have developed two ways to make quantities of sub-300 nm magnetic particles. Post Particles (a) have been developed in our lab and involves patterning posts from photoresist using photolithography.Templated electrodeposition (b) is a simple and efficient method of producing size-uniform magnetic rods and has largely been a

Particles:Force measurements within intracellular trafficking experiments require magnetic particles that mimic endogenous vesicles, and therefore need to be in the size range of 300nm or less in diameter (uniform magnetic particles of this type are not commercially available). A second requirement is chemical and special specificity of attachment. One example is the case of cilia studies, where we seek to attach one bead to only one cilium. We have developed two ways to make quantities of sub-300 nm magnetic particles. Post Particles (a) have been developed in our lab and involves patterning posts from photoresist using photolithography.Templated electrodeposition (b) is a simple and efficient method of producing size-uniform magnetic rods and has largely been a  dopted from the literature. These rods can be grown with aspect ratios varying from 1 to 100+ and diameters ranging from 18nm to 250nm. Electrochemical deposition (c-e) can use multilayers of metals, including magnetic materials, sequentially deposited and then the nanorods can be released from a template. To minimize the attachment site to a single location, we have developed

dopted from the literature. These rods can be grown with aspect ratios varying from 1 to 100+ and diameters ranging from 18nm to 250nm. Electrochemical deposition (c-e) can use multilayers of metals, including magnetic materials, sequentially deposited and then the nanorods can be released from a template. To minimize the attachment site to a single location, we have developed

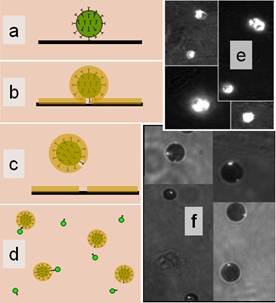

Spot Labeled beads (a-f), where a simple processing step results in a single small site that retains the original functionalization chemistry of the bead.